Patagonia West Bund achieves RESET Embodied Certification

When the design team walked into the raw space of the future Patagonia flagship, the first thing they noticed was that it wasn’t ready for interior construction. Taking over approximately 500 square meters of a refurbished industrial building in a former shipyard, the space still needed some architectural work.

Rather than create something overly custom for Patagonia, the design team’s response was to complete the building so that it could also be used by future tenants, with minor changes. Retail stores tend to be ephemeral, changing many times over the lifetime of a building. Just like hikers on a trail, the design team wanted their intervention to leave the site in a better state than when they found it.

Patagonia has a company goal of reducing Scope 3 greenhouse gas (GHG) emissions by 55% and 90%, by 2030 and 2040 respectively. In simple English, reducing Scope 3 emissions includes reducing the impact of store construction.

By necessity, the pre-work required on the building - including the buildout of a subfloor and completion of the facade - would raise the overall GHG emissions from store construction. This reality further motivated the design team to find ways to mitigate the impact of their work.

The most common design approach for a flagship store would have been to finish the building in a way that was unique to Patagonia. By definition, this would have required the next tenant to demolish everything and start over. Instead, the designers chose to finish the building in a way that was more timeless and true to the structure - something that would outlast them. The remainder of the intervention - the Patagonia design - would be industrial objects deposited into the space. Moreover, those objects would be designed for disassembly, reuse and recycling. In this way, the design team chose to celebrate the culture of the brand as opposed to the image.

The result is an authentic, unpretentious space that matches the brand ethos, the origins of the building and the sustainability goals of the project.

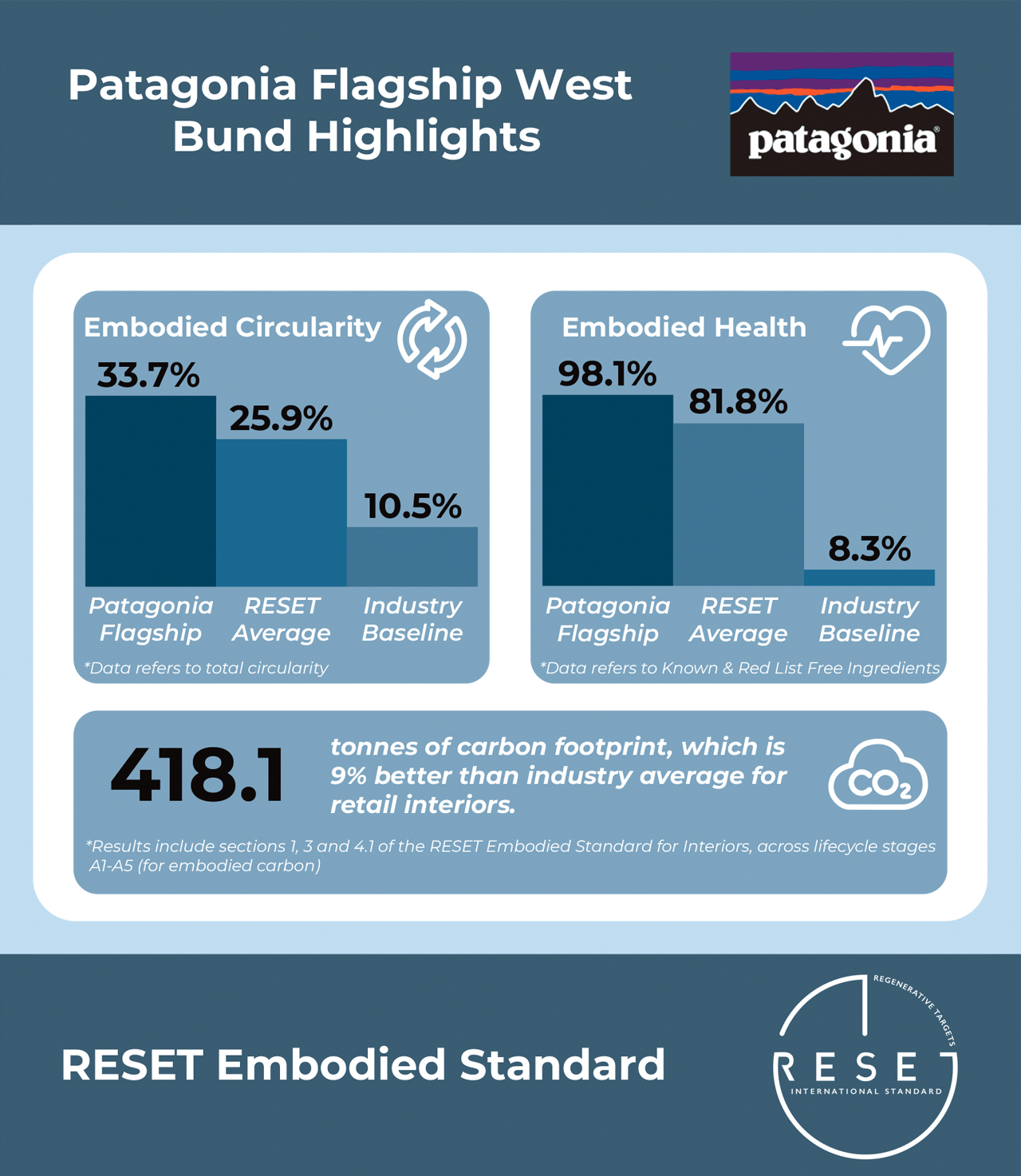

A closer look at the carbon, circularity, and health data of the Patagonia West Bund Store

The RESET Embodied Standard was chosen to measure the sustainability performance of the Patagonia West Bund flagship store, prioritizing real metrics over marketing badges. The RESET data was also used to benchmark results against similar projects.

Despite the need for additional materials to complete the shell of the building, the store achieved a carbon footprint that is 9% lower (i.e., better) than similar stores. This was achieved by limiting the amount of interior materials and a focus on local sourcing. This reduction does not account for the potential of most materials to be disassembled, reused and/or recycled, all strategic design choices that will further reduce emissions in the future.

"Typically, about 95% of retail interiors goes to landfill or incineration," says Sacha Silva, the interior architect of the project. "That’s not only an incredible waste of resources, but also money. In this store, most of the fixtures have been designed to be reused in the next store, saving materials and money."

Reuse is - however - never a guarantee. The only guarantee is that all materials eventually reach an end of life. In a perfect world, that end of life is recycling or biocycling.

For this reason, just over 2/3 of the Patagonia flagship can be recycled or biocycled at the end of life, yielding a total circularity of 33.7% - a result which is 3 times better than similar stores.

To achieve this, the design team chose to limit the amount of biomaterials in favor of metals and mineral based materials.

The ability of biomaterials to be biocycled - such as plywood and MDF - is almost always compromised by adhesives and finishes. Even when non-toxic adhesives and finishes are used, facilities to compost or biodegrade construction materials do not yet exist, fating them to incineration or landfill.

The use of metals and mechanical assemblies were prioritized for the millwork and fixtures, creating the opportunity for these items to be reused in the future. At their eventual end-of-life, the ability to cleanly disassemble the metals and their high financial value increases almost guarantees their recycling. Solid reclaimed wood is used sparingly and can also be disassembled for reuse. This approach virtually eliminated the use of MDF - one the most used materials and biggest challenges in retail interiors.

Mineral based materials - local terrazzo and cement-sand screed - were selected for the subfloor and floor finish with the intent of looking original to the building, outlive the store and be reused ‘as is’. As a fallback, even though the floor assembly can not be disassembled, the fully mineral-based materials can be cleanly removed and crushed into aggregate and sand for future flooring assemblies.

The high level of circularity was also achieved by ensuring that materials weren’t compromised by harmful chemicals. In terms of healthy materials, the flagship out-performed high performance RESET projects by 17%. With 98.1% of the material ingredients in the flagship that are known and free of harmful chemicals, the health performance is 12 times better than similar projects.

Key metrics include:

In quantifying the impact of the West Bund flagship, Patagonia brings science into store design and experience. This approach not only helps the brand better understand the levers for reducing the environmental footprint of their retail spaces, it also sets a baseline and defines a path for measuring continuous improvement. Hopefully, it also inspires others to do the same.

About Patagonia

We’re in business to save our home planet. Founded by Yvon Chouinard in 1973, Patagonia is an outdoor apparel company based in Ventura, California. As a certified B Corporation and a founding member of 1% for the Planet, the company is recognized internationally for its product quality and environmental activism, as well as its contributions of nearly $200 million to environmental organizations. Its unique ownership structure reflects that Earth is its only shareholder: Profits not reinvested back into the business are paid as dividends to protect the planet.

About RESET Standard

RESET Standard is a non-profit organization providing a global framework for measurable sustainability in the built environment. Through performance and data-driven standards, RESET helps organizations reduce environmental impact and improve human health.

For more information about RESET, please visit: https://resetstandard.org/.